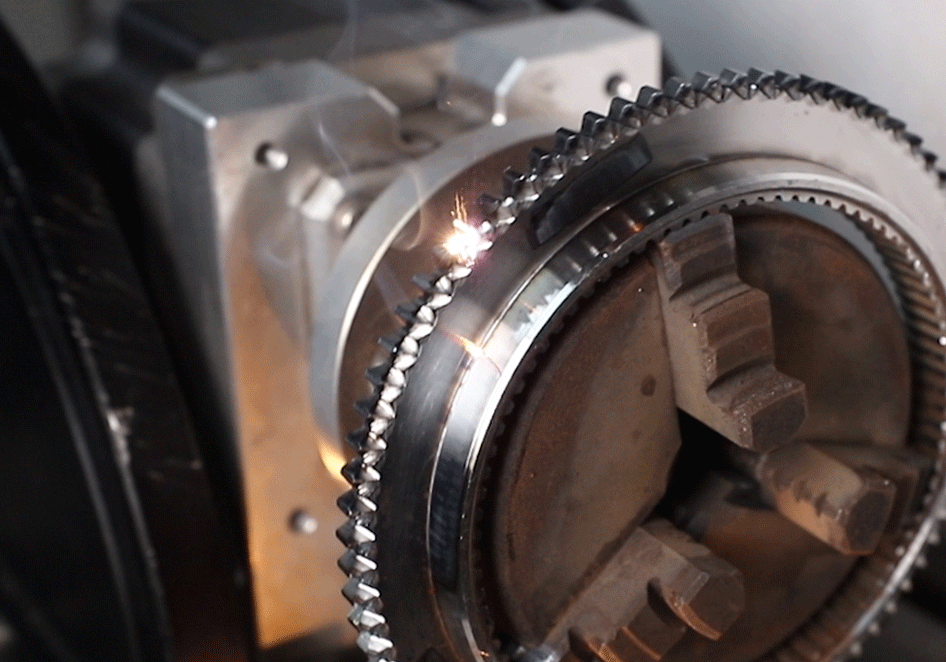

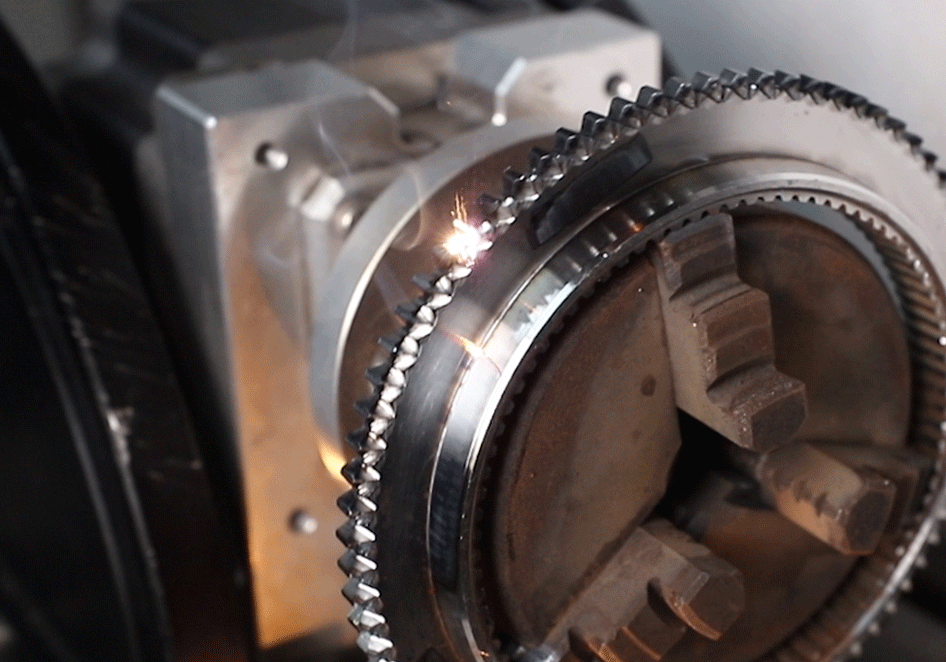

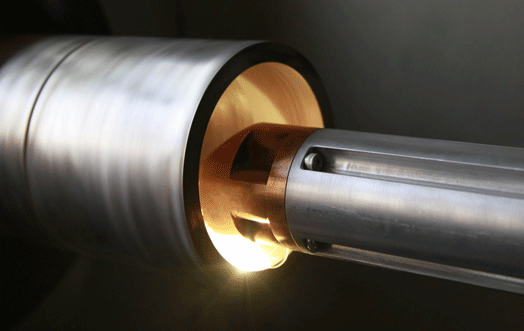

The laser is currently the heat source with the highest energy density, and has good directionality, monochromaticity and coherence. Using these characteristics, the surface of the metal or part is optimized (including laser phase hardening, laser glazing, laser alloying and laser coating, etc.) can change the microstructure of the surface of the metal or part, thereby improving its mechanical and physical and chemical properties, as far as the mechanical industry is concerned, mainly to improve the wear resistance, corrosion resistance and fatigue resistance of parts.