Applications: Laser marking of stainless steel

The invention of stainless steel dates back to the First World War. In order to solve the problem of bore wear, the British metallurgy expert Harry Brearley carried out the development of alloy steel, the experiment was unintentionally found in the alloy steel to add chromium, nickel and other elements can make steel with excellent anti-rust performance. Today, this material has been widely known, because of its excellent corrosion resistance, wear resistance and other properties, in the home appliances, kitchen utensils, automobiles, building materials, medical equipment and other industries are widely used.

Stainless steel products are often marked with numbers, bar codes / two-dimensional code, patterns, etc., to meet the product traceability or aesthetic needs. Laser marking green, efficient, flexible high, can be permanently retained, has been widely used in stainless steel products logo, marking white, black marking is often used. Laser is applied to stainless steel material, can also produce colorful colors, in the color of stainless steel endlessly used in construction, automotive, arts and crafts and other fields today, laser color marking for people to provide a new and efficient solution. Chemical coloring, electrochemical coloring and other traditional methods of preparing color stainless steel high energy consumption, pollution, difficult to achieve fine coloring, in contrast, stainless steel laser color marking has unique advantages.

Principle of Laser color marking

In 1999, Ann Marie Carey initial attempt to mark color in the niobium bowl to make metal crafts and jewelry laser color marking becomes feasible. Since then, the scope of application of laser color marking has been expanded, it has also become a new product value-added process methods.

Stainless steel material in the role of the laser heat source, the surface generates colored oxides, or generate a layer of colorless and transparent oxide film, due to light interference effect of the film presents a variety of colors, which is the basic principle of stainless steel color marking.

Stainless steel in the metal element oxidation of the product itself will show color. Table 1 for the stainless steel surface by the laser oxidation of several major oxide color.

In the appropriate laser energy, the surface of stainless steel will form a layer of colorless transparent oxide film, this layer of film will produce interference phenomenon.

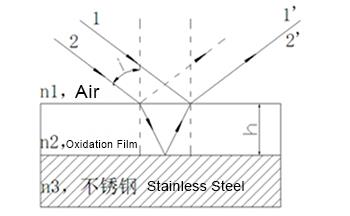

As shown in Figure 1, a beam of light incident to the oxide film surface, the light beam in the oxide film surface simultaneously reflection and refraction. The light 2 is refracted into the oxide film on the surface of the air-oxide film, and is reflected on the surface of the oxide film-stainless steel to finally emit light 2 '. The reflected ray 1' of ray 1 coincides with ray 2 'to form the interference beam. When the crest and peak of 1 ' coincides with the crest and peak of 2 ', the light vibration to strengthen; is the crest coincides with peak to light vibration weakened.

The difference in the optical path between the light ray 1 'and the light ray 2' can be represented by the formula (1).

Where n1 is the refractive index of the air, n2 is the refractive index of the oxide film, i is the incident angle of light, and h is the thickness of the oxide film.

If the light wavelength is λ, when the optical path difference is δ = kλ + λ / 2 (k = 0, 1, 2, 3, ...), the optical vibration is weakened. White is composed of red, orange, yellow, green, cyan, blue, purple seven color composite light composition. It can be seen from Equation (1) that the specific color of the light after the interference occurs is enhanced, depending mainly on the thickness of the oxide film. Equation (1) also shows us that when the human eye viewing angle is not the same, the color of the oxide film will change. This is the principle of oxidation film interference color.

We can know from the equation (1), when the optical vibration is enhanced, the optical path difference δ = kλ (k = 1, 2, 3, ...). From this we can deduce formula (2):

Light from the red, orange, yellow, green, cyan, blue, purple gradually change, the wavelength becomes shorter. From the formula (2) shows, in theory, at an appropriate angle, with the oxide film thickness increases, the laser marking the color will be purple → blue → cyan → green → yellow → orange → red in the order of change .

As we have seen, the thickness of the oxide film determines the color we see in a given viewing angle. While the thickness of the oxide film is directly determined by the incident laser energy. Here the use of Maxphotonics laser products smart laser marker marking color on stainless steel. The product is shown in Figure 2.

Brief Introduction :

Smart laser is one of the cutting-edge products of MAX Laser. It has many advantages such as small size, light weight, high integration, energy saving and environmental protection. Its compact structure, the internal integration of computer systems, laser control systems, motion control systems, the best choice for laser marking.

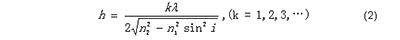

In the experiment, it is SUS304 stainless steel. Before the laser marking, it was wiped with industrial alcohol. In the different amount of defocus, respectively, to change the laser power, laser frequency to change the color.

In Fig. 3, the defocus amounts are taken as +4 mm, +3 mm, +2 mm, +5 mm, respectively. Marking color plate, the abscissa of laser power, from 35% to 75% at equal intervals increments, the ordinate for the laser frequency, from 20kHz to 35kHz equal interval increments. The viewing angle is 60 ° (60 ° to the surface of the workpiece). In Fig. 3 (c), when the out-of-focus amount is +2 mm, the surface of stainless steel in most of the marking blocks is burned to the yellow to black, the surface of the material is close to the focal point, the laser energy density is too large, The color palette is not rich enough. It can be seen from (a), (b), (d), in the frequency range of 20 ~ 35kHz, when the laser power is constant, with the laser frequency changes, marking color is almost unchanged. Marking color mainly changes with the laser power change. When the out of focus for the +3 mm, at a certain frequency, with the laser power increases, marking the color change rule: yellow → blue → light green → pink → purple → dark purple → yellow; When the amount of defocusing is +4 mm, with the increase of laser power, the change of marking color is as follows: light yellow → golden → dark blue → yellow green → purple → dark green; , When if for +4 mm, Marking color change as follows: yellow → golden → light blue → yellow → purple → dark green. These laws are generally consistent with the laws of the previous theoretical derivation.

Finally , the stainless steel laser color marking technology is still need to be improved. For example, marking color is not very rich, color marking effect debugging more difficult, and so on. However, the laser technology from birth to today's increasingly wide range of applications, but also half a century. As the rapid development of laser technology to bring the world the surprise and convenience, laser color marking technology will continue to move forward to the power of science and technology to make the industry and life better.