Ten Common Problems and Solutions in Carbon Steel Laser Cutting

Laser cutting is one of the thermal cutting methods, using a focused high-power laser beam irradiate the workpiece, so that the material is rapidly melting, vaporization, ablation or burning, while coaxial with the beam through the high-speed air blown molten material , So as to achieve to cut the workpiece. Laser cutting is suitable for cutting steel plate and carbon steel with large thickness and long length, and has been widely used in industrial production.

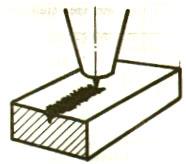

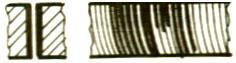

In the case of normal cutting conditions, cutting carbon steel effect (as shown below) should be no glitches, the same traction line.

But in the actual process due to improper operation debugging, problems may occur, refer to the following problems to exclude , and adjust.

1. the bottom of the traction line has a large offset, the bottom of the incision wider

Possible Causes

(1) Feed rate is too high (2) Laser power is too low (3) Air pressure is too low (4) Focus is too high Solutions

(1) Reduce the feed rate (2) Increase the laser power (3) Increase the pressure (4) Reduce the focus

2. the bottom surface of the burr like slag, into a drop-like and easy to remove.

Possible Causes

(1) The feed rate is too high (2) The air pressure is too low (3) The focus is too high

Solutions

(1)to reduce the feed rate (2) increase the pressure (3) reduce the focus

3. together with the metal burr can be removed as a block

Possible Causes

(1) The focus is too high

(2) the solution

(3) reduce the focus

4. the bottom of the metal burr is difficult to remove.

Possible Causes

(1) Feed rate too high (2) Air pressure too low (3) Gas impure (4) Focus too high Solutions

(1) Reduce the feed rate (2) Increase the air pressure (3) Use a more pure gas (4) Reduce the focus

5. only in the side of the sheet metal incision burr.

Possible Causes

(1) Nozzle alignment is not correct (2) Nozzle is defective Solution

(1) Centering Nozzle (2) Change nozzle

6. the material discharge from the above.

Possible Causes

(1) Power is too low (2) Feed rate is too high Solutions

In this case, press the pause button immediately to prevent the slag from splashing onto the focusing mirror. Then increase the power and decrease the feed rate.

7. the workpiece is not cut through.

Possible Causes

(1) Machining gas error (N2) (2) Feedrate too high (3) Power is too low Solution

(1) In this case, press the pause button immediately to prevent the slag from splashing onto the focusing mirror (2) the use of oxygen as the processing gas (3) to reduce the feed rate increase power

8.cutting the surface is not precise

Possible Causes

(1) The air pressure is too high (2) The nozzle is damaged (3) The nozzle diameter is too large (4) The material is not good Solution

(1) Reduce the air pressure (2) Replace the nozzle (3) Install the appropriate nozzle (4) Use a smooth surface of uniform material

9. no glitches, traction line tilt, incision at the bottom becomes more narrow

Possible Causes

Feedrate too high Solution

Reduce the feed rate

10. cutting the surface texture is very rough

Possible Causes

(1) The focus is too high (2) The air pressure is too high (3) The feed rate is too low (4) The material is too hot Solution

(1) Reduce the focus (2) Reduce the air pressure (3) Increase the feed rate (4)

Maxphotonics MFSC series of single module CW fiber laser, high-precision cutting stainless steel, carbon steel and other metal materials, providing excellent laser process solutions to meet customer demand for a variety of laser equipment.